8월 28일 월요일

오전에 조금 일찍 일어나서

밀린 다이어리를 썼다

점심과 저녁은 두끼 다 얻어 먹었다

지난주 평일 중 저녁에도 모임이 있었는데

월요일 저녁에도 모임이 있었다

사람들과 있을때는 텐션을 유지하려고 하지만

이 날은 컨디션이 좀 안좋아서

(월요일은 항상 저기압이다)

말도 많이 못하고 조용히 있어서

같이 밥 먹은 분들께

좀 죄송했던 하루였다

8월 29일 화요일

출근하고 오전에 편의점에 들려서

1+1 음료수를 사고

하나는 옆자리 대리님을 드렸다

점심땐 김밥 한 줄을 먹었는데

치즈김밥에 치즈가 없었다

그냥 넘어가려고 했는데

다행히 같이 밥먹은 분께서

김밥집에 전화를 걸어서 500원을 돌려받았다

오후에 사내 편의점에서

미니 롤케익은 하나 사와서

일하면서 먹었다

이상하게 부지런하게 일을해도

일은 안줄어들고

점점 늘어나고 있다

8월 30일 수요일

아침에 좀 일찍 일어났다

일어나서 노트북을 켜고

이것저것 찾아봤다

요즘 진로에 고민이 많은 오춘기를 보내고 있다

점심은 쌀국수를 먹었다

쌀국수보다 볶음 국수가 더 맛있었다

퇴근하고 집에 도착하니

인터넷으로 주문한

분리수거함이 도착해서

분리수거함을 조립했다

사실 조립이랄것도 없었는데

밑에 다리만 달면 완성이었다

집이 한층 깔끔해진것 같아서

보기 좋았다

분리수거함을 만들고

저녁에는 김치찜을 시켜 먹었다

요즘 생활비 관리를 거의 안하고 있다

정신 차려야겠다

8월 31일 목요일

아침 저녁으로 회사 편의점에서 사먹은 것들

2+1 요거트는 역시 옆자리 대리님한테

하나를 나눠줬다

지난번에 먹은 롤케익이 맛있어서

이 날도 롤케익을 사먹었다

목요일은 좀 일찍 퇴근했다

별 일은 없었는데

그냥 퇴근하고 싶어서 퇴근을 했다

우리 회사는 한시간 단위로 연가를 쓸 수 있어서

이런게 자유로워서 좋다

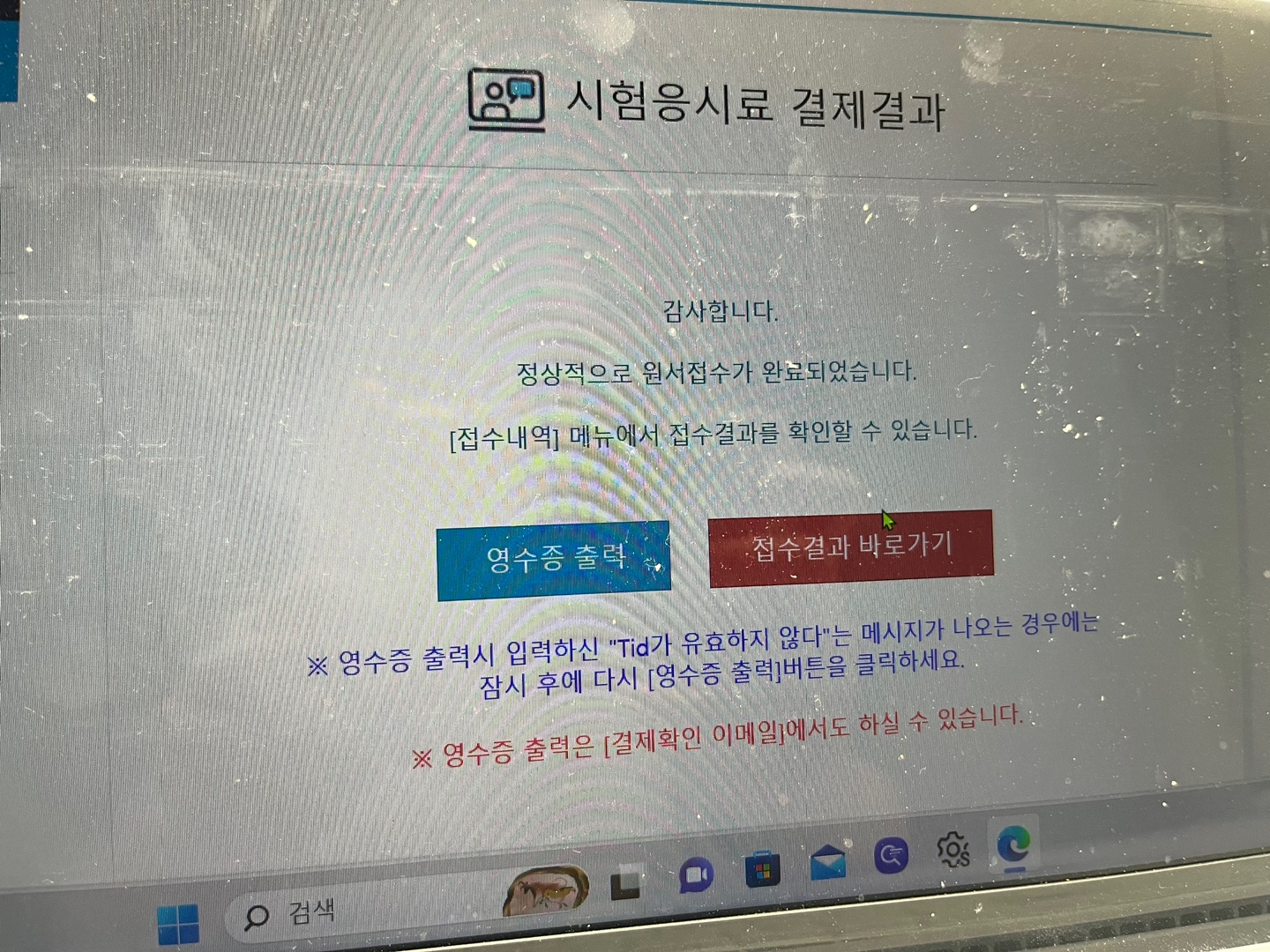

퇴근하고 세무회계 자격증 시험 접수를 했다

이 날 시험이 열렸는데도 불구하고

서울에 자리 남은 시험장이 한 곳밖에 없었다

사람들 참 열심히 살고 있구나 라고

느낄 수 있었다

저녁은 어제 먹다 남은

김치찜을 조금 덜어서

데워 먹었다

9월 1일 금요일

금요일 새벽 기상

한시간 일찍 출근을 하느랴고

일찍 일어나서 출근 준비를 했다

점심에는 우리 부서에 새로 오신 분과

닭갈비를 먹었다

닭갈비에 볶음밥은 디저트 아니냐면서

밥도 야무지게 볶아 먹었다

한시간 일찍 출근하고

한시간 일찍 퇴근하려고 했는데

어쩌다 보니 정시 퇴근을 했다

집에 와서 입맛이 없어서

비빔면을 대충 먹고

다이어리를 펼쳤더니

한 주동안 한글자도 안적어서

부랴부랴 다이어리를 정리했다

9월 2일 토요일

주말 아침

일찍 일어나서

동네 떡집에서 떡을 포장해왔다

사온 떡은 아침으로 야무지게 먹었다

다음주에 할머니 생신이여서

오후에는 케이크를 하나 사서

할머니네로 갔다

할머니네서 저녁을 먹었는데

내가 좋아하는 고등어구이가 나왔다

9월 3일 일요일

일요일 오전

할머니랑 케이크를 잘라 먹었다

촛불 끄기 전에

소원빌고 끄라고 하니까

소원을 아주 길게 비시더니

후 하고 초를 끄셨다

케이크를 할머니가 잘라주었는데

자르고 나서 보니까

케이크 손잡이로 잘못 잘랐다

"이런것도 다 추억이지" 하시는

긍정적인 우리 할머니

케이크를 먹고

원래는 맛있는걸 사드릴려고 했는데

배부르시다고해서

동네 카페에서 음료 한잔을 했다

할머니가 먹고 싶다고 고르신

키위주스와

할머니께 맛보여 드리고 싶어서

내가 고른 레몬 마들렌

요즘들어

'행복한 삶이란 무엇일까?'하는 생각이 든다

오랜 타지생활에서 오는

향수병인지

연봉을 포기해서라도

다시 고향으로 돌아가고 싶다